Subsea NORM Detector

At Petritek, we are dedicated to advancing the safety and efficiency of subsea operations…

Fixed Topside NORM Detectors

At Petritek, We are committed to ensuring the safety and integrity your operations. Our Fixed Topside NORM…

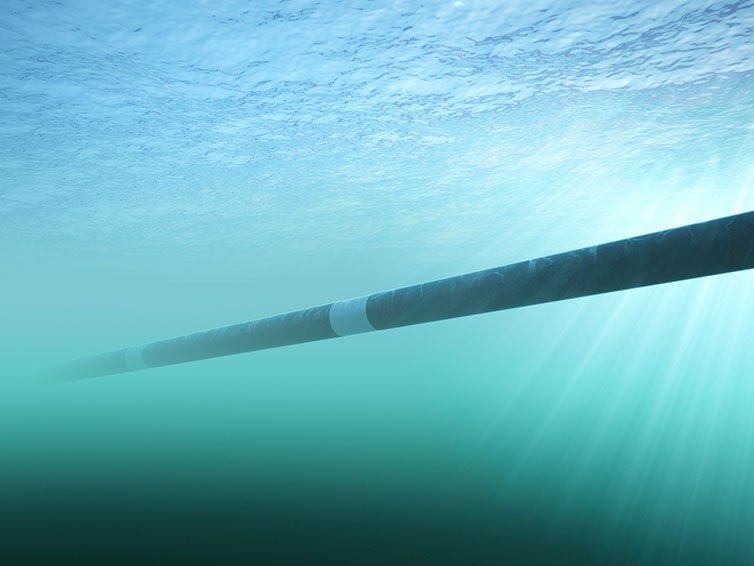

Cable Repairs

At Petritek, we specialise in providing top-notch cable repair services that ensure the longevity and reliability of your…

Waste Acquisition and Spatial Sampling Process (WASSP)

At Petritek we pride ourselves on developing innovative solutions that address complex challenges in waste management…

Pig Tracking

Petritek can design and build the solution you need. Learn more what is Pig Tracking?

Controlled Environment Transport Containers

At Petritek, we are at the forefront of innovation with our state-of-the-art controlled environment transport containers…

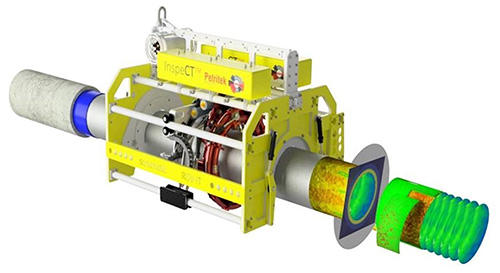

CT Scanner

At Petritek, we are dedicated to breaking barriers and providing state-of-the-art inspection results with our advanced CT Scanner technology…