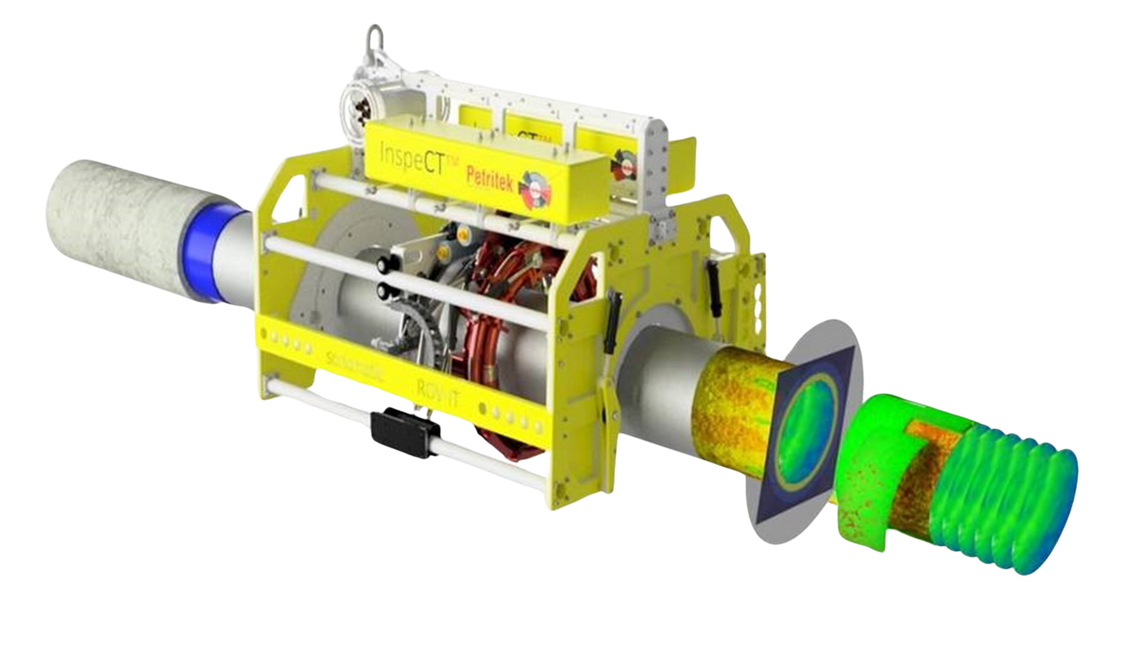

At Petritek, we are dedicated to breaking barriers and providing state-of-the-art inspection results with our advanced CT Scanner technology. Our solutions offer true non-destructive testing, ensuring comprehensive and accurate analysis without the need for marine growth or coating removal. Discover how our CT Scanner can transform your inspection processes.

Our CT Scanner is a cutting-edge non-destructive testing (NDT) solution designed to provide precise and reliable inspection of various pipeline components. By utilising advanced imaging technology, our CT Scanner delivers detailed visualisations and data, enabling thorough analysis and assessment.

Key Features and Innovations of Petritek’s

CT Scanner

Advanced Non-Destructive Testing Techniques

- True Non-Destructive Testing: Our CT Scanner allows for comprehensive inspection without the need for marine growth or coating removal. This ensures the integrity of the inspected materials remain intact, while providing accurate and reliable results.

- Innovative Solutions for Various Applications: Our CT Scanner is designed to address a wide range of inspection needs, including

- Concrete Coated Pipes: Detailed imaging and analysis of concrete-coated pipelines.

- Corrosion and Wall Loss Mapping: Accurate mapping of corrosion and wall loss to assess structural integrity.

- Deposition characterisation: Identification and characterisation of depositions within pipelines.

- Flow Assurance: Ensuring the smooth operation of pipelines by detecting and analysing potential blockages.

- Pipe-in-Pipe and Caissons: Comprehensive inspection of complex pipeline structures.

- Flexible Risers and Flow Lines: Detailed analysis of flexible risers and flow lines for potential faults and defects.

Software and Automation Development

- Proprietary Software Development: Our CT Scanner is supported by advanced proprietary software for modeling, data acquisition, image analysis, and visualisation. This includes:

- Automatic Fault/Feature/Defect Detection: Identifying and analysing faults and features automatically for accurate assessment.

- Analysis and Sizing: Precise sizing of defects and features for comprehensive reporting.

- Ovality Assessment: Evaluating the ovality of pipes to ensure structural integrity.

- Modeling of Radiation Levels: Accurate modeling of radiation levels to ensure safety and compliance.

Near-Real-Time Results

- Immediate Insights: Clients are able to view results and assess pipelines on-site in near-real-time. This allows for immediate decision-making and action, reducing downtime and enhancing operational efficiency.

Applications of Petritek’s CT Scanner

Wide Range of Applications

- Oil and Gas Industry: Ensures the integrity and safety of pipelines used in oil and gas extraction and transportation. Our CT Scanner technology provides high-resolution imaging and accurate data analysis, crucial for detecting corrosion, wall loss, and potential blockages. By identifying these issues early, our technology helps prevent leaks and ruptures, ensuring safe and efficient operation of oil and gas pipelines.

- Marine and Offshore Engineering: Provides detailed inspection and analysis of marine and offshore structures, including risers and flow lines. The harsh marine environment can accelerate wear and tear on these structures. Our CT Scanner offers non-destructive testing that can detect internal and external defects without the need for marine growth or coating removal. This allows for thorough inspection and maintenance planning, ensuring the longevity and reliability of marine infrastructure.

- Industrial Infrastructure: Supports the maintenance and inspection of industrial pipelines and structures, ensuring operational efficiency and safety. Industrial facilities often operate under extreme conditions and any failure in pipeline integrity can lead to significant downtime and financial loss. Our CT Scanner helps in regular maintenance by providing accurate mapping of corrosion and depositions, facilitating proactive maintenance and reducing the risk of unexpected failures.

Success Stories of Petritek’s CT Scanner

Case Study 1: Comprehensive Corrosion Mapping for Offshore Oil Platform

- Task: Conduct a thorough inspection of an offshore oil platform’s pipelines to map corrosion areas accurately.

- Challenge: The offshore environment posed significant challenges, including harsh weather and remote location logistics. Accurate corrosion mapping was essential to prioritise maintenance and prevent pipeline failures.

- Solution: Our CT Scanner was deployed to perform a detailed inspection of the platform’s pipelines. The advanced imaging technology provided high-resolution maps of corrosion areas.

- Outcome: The precise data enabled the maintenance team to effectively prioritise repairs and replacements. This proactive approach prevented potential failures, optimised the maintenance schedule, and significantly reduced downtime, thereby enhancing overall operational efficiency.

Case Study 2: Flow Assurance Inspection for Major Gas Pipeline

- Task: Inspect a critical gas pipeline to identify and resolve potential flow restrictions before they cause significant issues.

- Challenge: The gas pipeline was suspected of having flow blockages that could disrupt operations. Immediate and accurate identification of these blockages was crucial.

- Solution: Our CT Scanner was utilised to perform a high-resolution inspection of the gas pipeline. The imaging technology identified multiple areas where deposition was causing blockages.

- Outcome: By addressing these blockages promptly, the client ensured uninterrupted gas flow, avoided costly downtime and enhanced the safety and reliability of their pipeline network. The advanced data analysis, provided by our CT Scanner, facilitated informed decision-making and efficient resolution of potential issues.

Benefits and Advantages

Why Choose Petritek’s CT Scanner Technology?

- Enhanced Safety: Our CT Scanner ensures the integrity of critical infrastructures, significantly reducing the risk of pipeline failures and environmental hazards. By detecting potential issues such as corrosion, wall loss, and deposition before they escalate, our technology helps prevent accidents and ensures the safety of both personnel and the environment.

- Cost Efficiency: By providing highly accurate and detailed inspection data, our CT Scanner minimises maintenance costs and prevents costly downtime. Early detection of issues allows for targeted repairs and maintenance, reducing the need for extensive overhauls and ensuring that resources are used efficiently.

- Regulatory Compliance: Our CT Scanner technology meets and exceeds industry standards and regulations, ensuring that your operations remain compliant with all relevant guidelines. This not only helps in avoiding regulatory penalties but also provides peace of mind for operators and stakeholders, knowing that their infrastructures is maintained to the highest standards.

- Comprehensive Insights: Our CT Scanner offers in-depth insights into the condition of pipelines and structures. The detailed imaging and analysis capabilities support informed decision-making and proactive maintenance planning. This ensures that potential issues are addressed before they become critical, enhancing the overall reliability and longevity of your infrastructures.

Contact Us

Contact us today to learn more about our solutions and how we can help your business.

- [email protected]

- 1300 819 557

- 75 Farrall Rd, Midvale WA 6065